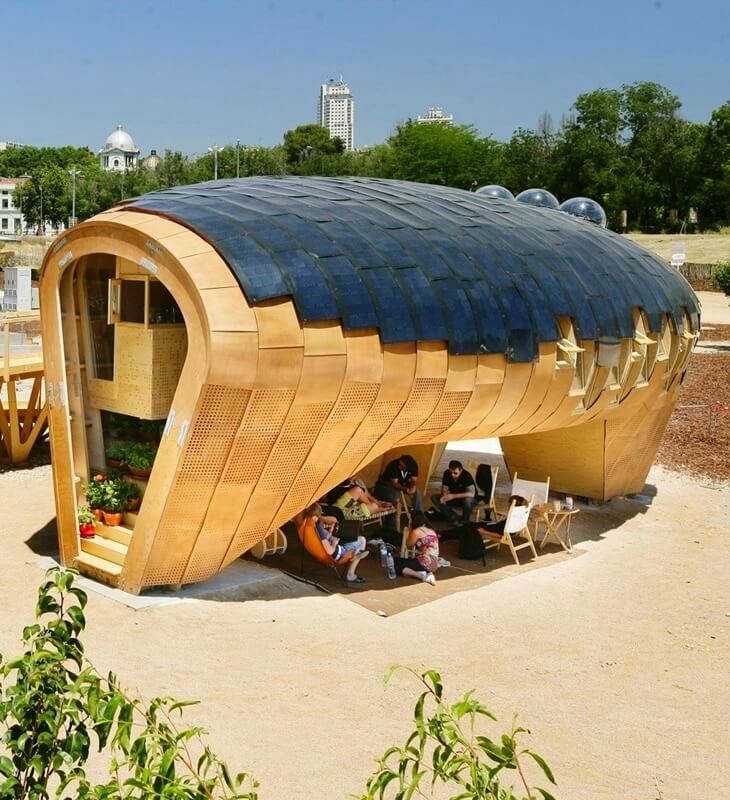

How Can CNC Technology Make Investing in Modular Homes More Attractive?

Computer Numerical Control (CNC) machining is an innovative technology that has already helped numerous companies. It covers a wide range of manufacturing needs, making it an outstanding solution for businesses operating in the industrial sector. However, one area that may also benefit from the use of CNC machines is real estate development, namely modular construction.

Nowadays, where time is of the essence, not everyone has time to search for Sea Pines Real Estate villas for sale or build a multi-level home from the ground up. As a result, opting for a modular home has become an attractive option. It allows homeowners to reduce construction costs, produce less waste during construction, and move into their new homes faster than usual.

CNC services can be a stellar investment in this department, further accelerating the process of designing and building a modular home. Because CNC machining is automated, there is no need for constant human oversight. Additionally, it goes hand-in-hand with modular construction’s flexibility, as the machines can be programmed to perform specific and precise routines.

Here is how CNC technology can make investing in modular homes more attractive:

It Can Speed Up the Construction Process

As mentioned before, time is of the essence for many people. And when it comes to building a home, this couldn’t be truer. No one wants to spend months or even years in construction limbo.

Modular homes are the perfect solution for those who want to move into their new place as soon as possible. And with the help of CNC machines, the process of creating a modular home can be even further accelerated.

CNC machines can help create various parts and components of a modular home faster than if traditional methods were used. This is because they can be programmed to perform repetitive tasks quickly and efficiently. Once the initial programming is complete, the CNC machine can do the rest on its own, without the need for human intervention.

In other words, with CNC technology, there is no need for workers to be present all the time during the construction process. This, in turn, can help reduce construction costs and speed up the process significantly.

Additionally, CNC machines can work around the clock if necessary, meaning that production can be increased without compromising quality. This solution is ideal for developers who are working on tight deadlines and need to have their homes ready as soon as possible.

It Can Enhance the Quality of Modular Homes

While modular homes are already known for their high quality, CNC technology can help take things to the next level. CNC machines are highly precise and can perform repetitive tasks flawlessly. Because of this, every component of the modular home created with this technology will be identical, ensuring that the final product is of the highest possible quality.

Furthermore, CNC machines are known for their accuracy and precision. When used in modular construction, this can result in homes that are built to last. Additionally, because CNC machines can be programmed to perform repetitive tasks, there is less room for human error.

What’s more, CNC machines can be used to create custom components for modular homes. This way, developers can design and build unique homes that stand out from the rest, further increasing their appeal. It can be a major selling point, as more and more people want their homes to stand out from the rest.

It Can Reduce Construction Waste

Modular construction is known for being environmentally friendly. After all, it uses fewer materials than traditional construction as well as cuts down on waste. Nonetheless, there is still room for improvement in this department.

By employing CNC technology, developers can build homes at a lower cost and with a smaller environmental footprint. This is due to the fact that CNC machines are capable of producing precision parts with minimal waste. These machines are extremely precise and can cut materials with great accuracy. As a result, there is very little material waste when using this technology. This is good news for both the environment and your wallet!

It Can Reduce Construction Costs

CNC technology can also help reduce construction costs in several ways. First of all, it can help speed up the production process, meaning that you will need less time and resources to complete the project. CNC machines are also relatively low-maintenance, which further reduces operating costs.

What’s more, thanks to the high level of precision offered by CNC machines, there is less room for error. As a result, developers will waste fewer materials, further reducing construction costs.

The machines can also be programmed to perform specific tasks, like cutting flooring or drilling holes. As such, there is no need for workers to do this manually. It saves time, as well as labor costs.

It Can Enhance Personnel Safety

When a construction project is in full swing, there is often little room for error. In fact, even the slightest mistake can have drastic consequences. To prevent losses, it is essential to put safety first.

The CNC technology contributes to this end by reducing the need for manual labor. It allows you to have fewer people working on the site, reducing the risks involved.

Rather than placing workers at risk, machines can be programmed to perform all the needed tasks. A reduction in personnel can undoubtedly help to reduce potential injuries, accidents, and fatalities while on the job, which is something contractors appreciate a lot.

Final Thoughts

While there are several reasons to invest in modular homes, CNC technology can make it even more beneficial. The technology provides significant benefits for businesses operating in the real estate industry, and it has the potential to make investing in modular homes more attractive than ever before.

CNC services can be of great assistance in the construction process, speeding up manufacturing processes and reducing costs. It also allows manufacturers to produce greater volumes of components with better accuracy. This, in turn, reduces waste and increases efficiency.

CNC machines can also reduce the number of errors during construction and help create a high-quality end product. With them boosting the modular construction process, you can receive a move-in ready home while saving time and money.